Resina para múltiples materiales con indicador de montaje

Esta resina de adhesión química AT-HP Plus abarca el 100 % de las aplicaciones habituales de mampostería maciza y hueca. Se puede utilizar sin riesgo en interior (COV A+) y garantiza una fijación fácil y eficaz gracias a una innovación exclusiva: el indicador de montaje Simpson Strong-Tie.

Detalles de producto

Características

Materia

- Resina de metacrilato.

- Varilla roscada : acero electrocincado y acero inoxidable A4-70.

Ventajas

- Alto valor de adhesión en el hormigón y la mampostería.

- Muy buen comportamiento en perforación húmeda y/o mojada.

- Resistencia al fuego.

- 2 DITE para las varillas roscadas en el hormigón y la mampostería.

- 1 DITE para la colocación de varillas de hierro en el hormigón.

Aplicaciones

Soporte

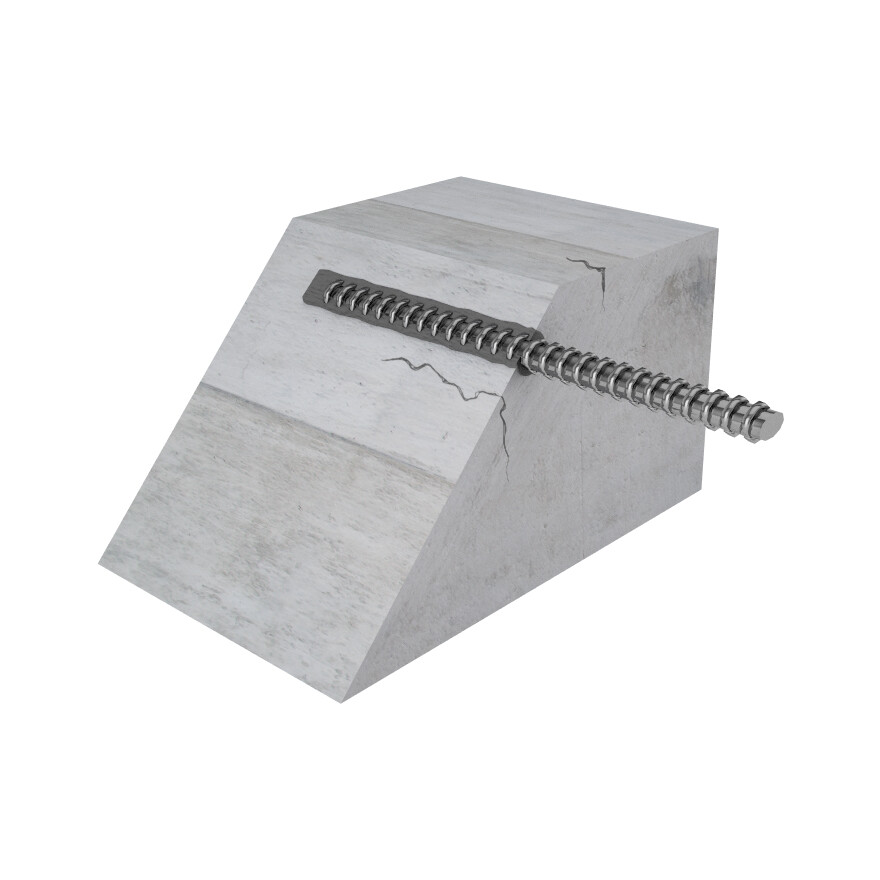

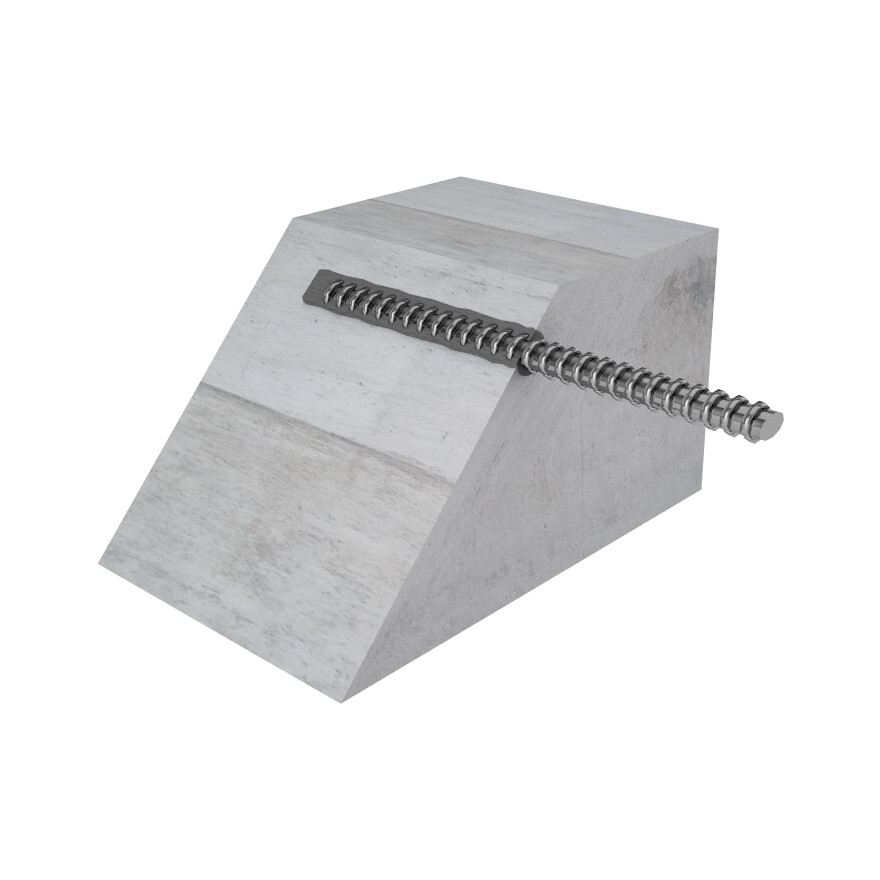

- Hormigón, hormigón celular.

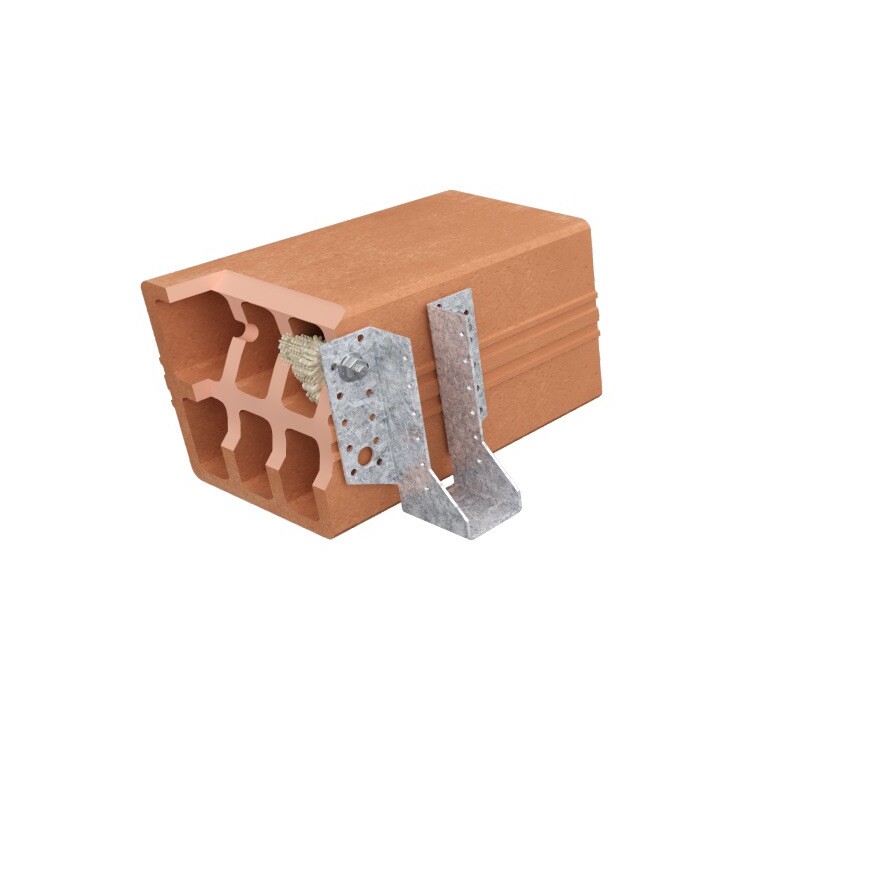

- Ladrillo hueco y macizo.

- Piedra sillar hueca y maciza.

Campos de aplicación

- Colocación de varillas de hierro en el hormigón.

- Fijación de vigas, escuadras de revestimiento de fachada.

- Fijación de vigas metálicas, grúas de puente.

- Fijación de barandillas, andamios.

Datos técnicos

Références

| Modelo | Product information | ||||

|---|---|---|---|---|---|

| Grey color | Beige color | Content [ml] | Weigth [kg] | Packaging qty [pcs] | |

| ATHP300PLUSG-FR | x | - | 300 | 0.575 | 12 |

| ATHP420PLUSG-FR | x | - | 420 | 0.828 | 12 |

Design resistance – Tension – NRd [kN] – hef = 8d – Carbon steel 5.8

| Modelo | Design resistance – hef = 8d – Carbon steel 5.8 | |||||||

|---|---|---|---|---|---|---|---|---|

| Tension - NRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 10.7 | 12 | 12 | 12 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 15.9 | 17.8 | 19.3 | 19.3 |

| AT-HP PLUS + LMAS M12 | 8.4 | 8.8 | 9 | 9.2 | 21.7 | 24.3 | 26.7 | 28 |

| AT-HP PLUS + LMAS M16 | 15 | 15.6 | 16.1 | 16.4 | 34.3 | 38.4 | 42.2 | 44.6 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 50.2 | 56.3 | 61.8 | 65.3 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 67.5 | 75.6 | 83.1 | 87.8 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Tension – NRd [kN] – hef = 12d – Carbon steel 5.8

| Modelo | Design resistance – hef = 12d – Carbon steel 5.8 | |||||||

|---|---|---|---|---|---|---|---|---|

| Tension - NRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 12 | 12 | 12 | 12 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 19.3 | 19.3 | 19.3 | 19.3 |

| AT-HP PLUS + LMAS M12 | 12.7 | 13.2 | 13.5 | 13.8 | 28 | 28 | 28 | 28 |

| AT-HP PLUS + LMAS M16 | 22.5 | 23.4 | 24.1 | 24.5 | 51.4 | 52.7 | 52.7 | 52.7 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 75.4 | 82 | 82 | 82 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 101.3 | 113.4 | 118 | 118 |

Concrete:

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Tension – NRd [kN] – hef = 8d – Stainless steel A4-70

| Modelo | Design resistance – hef = 8d – Stainless steel A4-70 | |||||||

|---|---|---|---|---|---|---|---|---|

| Tension - NRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 10.7 | 12 | 13.2 | 13.9 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 15.9 | 17.8 | 19.6 | 20.7 |

| AT-HP PLUS + LMAS M12 | 8.4 | 8.8 | 9 | 9.2 | 21.7 | 24.3 | 26.7 | 28.2 |

| AT-HP PLUS + LMAS M16 | 15 | 15.6 | 16.1 | 16.4 | 34.3 | 38.4 | 42.2 | 44.6 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 50.2 | 56.3 | 61.8 | 65.3 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 67.5 | 75.6 | 83.1 | 87.8 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Tension – NRd [kN] – hef = 12d – Stainless steel A4-70

| Modelo | Design resistance – hef = 12d – Stainless steel A4-70 | |||||||

|---|---|---|---|---|---|---|---|---|

| Tension - NRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 13.9 | 13.9 | 13.9 | 13.9 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 21.9 | 21.9 | 21.9 | 21.9 |

| AT-HP PLUS + LMAS M12 | 12.7 | 13.2 | 13.5 | 13.8 | 31.6 | 31.6 | 31.6 | 31.6 |

| AT-HP PLUS + LMAS M16 | 22.5 | 23.4 | 24.1 | 24.5 | 51.4 | 57.6 | 58.8 | 58.8 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 75.4 | 84.4 | 92 | 92 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 101.3 | 113.4 | 124.6 | 131.7 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Shear – VRd [kN] – hef = 8d – Carbon steel 5.8

| Modelo | Design resistance – hef = 8d – Carbon steel 5.8 | |||||||

|---|---|---|---|---|---|---|---|---|

| Shear - VRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 7.2 | 7.2 | 7.2 | 7.2 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 12 | 12 | 12 | 12 |

| AT-HP PLUS + LMAS M12 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 |

| AT-HP PLUS + LMAS M16 | 30 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 48.8 | 48.8 | 48.8 | 48.8 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 70.4 | 70.4 | 70.4 | 70.4 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Shear – VRd [kN] – hef = 12d – Carbon steel 5.8

| Modelo | Design resistance – hef = 12d – Carbon steel 5.8 | |||||||

|---|---|---|---|---|---|---|---|---|

| Shear - VRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 7.2 | 7.2 | 7.2 | 7.2 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 12 | 12 | 12 | 12 |

| AT-HP PLUS + LMAS M12 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 | 16.8 |

| AT-HP PLUS + LMAS M16 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 | 31.2 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 48.8 | 48.8 | 48.8 | 48.8 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 70.4 | 70.4 | 70.4 | 70.4 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Shear – VRd [kN] – hef = 8d – Stainless steel A4-70

| Modelo | Design resistance – hef = 8d – Stainless steel A4-70 | |||||||

|---|---|---|---|---|---|---|---|---|

| Shear - VRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 8.3 | 8.3 | 8.3 | 8.3 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 12.8 | 12.8 | 12.8 | 12.8 |

| AT-HP PLUS + LMAS M12 | 16.9 | 17.6 | 18.1 | 18.4 | 19.2 | 19.2 | 19.2 | 19.2 |

| AT-HP PLUS + LMAS M16 | 30 | 31.2 | 32.1 | 32.7 | 35.3 | 35.3 | 35.3 | 35.3 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 55.1 | 55.1 | 55.1 | 55.1 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 79.5 | 79.5 | 79.5 | 79.5 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Shear – VRd [kN] – hef = 12d – Stainless steel A4-70

| Modelo | Design resistance – hef = 12d – Stainless steel A4-70 | |||||||

|---|---|---|---|---|---|---|---|---|

| Shear - VRd [kN] | ||||||||

| Cracked concrete | Non-cracked concrete | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + LMAS M8 | - | - | - | - | 8.3 | 8.3 | 8.3 | 8.3 |

| AT-HP PLUS + LMAS M10 | - | - | - | - | 12.8 | 12.8 | 12.8 | 12.8 |

| AT-HP PLUS + LMAS M12 | 19.2 | 19.2 | 19.2 | 19.2 | 19.2 | 19.2 | 19.2 | 19.2 |

| AT-HP PLUS + LMAS M16 | 35.3 | 35.3 | 35.3 | 35.3 | 35.3 | 35.3 | 35.3 | 35.3 |

| AT-HP PLUS + LMAS M20 | - | - | - | - | 55.1 | 55.1 | 55.1 | 55.1 |

| AT-HP PLUS + LMAS M24 | - | - | - | - | 79.5 | 79.5 | 79.5 | 79.5 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Bending moment – MRd [Nm] – Concrete

| Modelo | Design resistance – Bending moment – MRd [Nm] | |

|---|---|---|

| Carbon steel 5.8 | Stainless steel A4-70 | |

| AT-HP PLUS + LMAS M8 | 15.2 | 16.7 |

| AT-HP PLUS + LMAS M10 | 29.6 | 34 |

| AT-HP PLUS + LMAS M12 | 52.8 | 59 |

| AT-HP PLUS + LMAS M16 | 133.6 | 149.4 |

| AT-HP PLUS + LMAS M20 | 260.8 | 291 |

| AT-HP PLUS + LMAS M24 | 448.8 | 502.6 |

Concrete :

1. The design loads have been calculated using the partial safety factors for resistances stated in ETA-approval(s). The loading figures are valid for unreinforced concrete and reinforced concrete with a rebar spacing s ≥ 15 cm (any diameter) or with a rebar spacing s ≥ 10 cm, if the rebar diameter is 10mm or smaller.

2. The figures for shear are based on a single anchor without influence of concrete edges. For anchorages close to edges (c ≤ max [10 hef; 60d]) the concrete edge failure shall be checked per ETAG 001, Annex C, design method A.

3. Concrete is considered non-cracked when the tensile stress within the concrete is\sigmaL +\sigmaR ≤ 0. In the absence of detailed verification\sigmaR = 3 N/mm² can be assumed (\sigmaL equals the tensile stress within the concrete induced by external loads, anchors loads included).

Design resistance – Tension – NRd [kN] – Rebar

| Modelo | Design resistance – NRd – Carbon steel 5.8 [kN] | |||||||

|---|---|---|---|---|---|---|---|---|

| Non-cracked concrete | ||||||||

| hef = 8d | hef = 12d | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + Ø8 | 6.3 | 7 | 7.7 | 8.1 | 9.4 | 10.5 | 11.5 | 12.2 |

| AT-HP PLUS + Ø10 | 10.5 | 11.7 | 12.9 | 13.6 | 15.7 | 17.6 | 19.3 | 20.4 |

| AT-HP PLUS + Ø12 | 14.1 | 15.8 | 17.3 | 18.3 | 21.1 | 23.6 | 26 | 27.4 |

| AT-HP PLUS + Ø14 | 19.1 | 21.4 | 23.6 | 24.9 | 28.7 | 32.2 | 35.3 | 37.3 |

| AT-HP PLUS + Ø16 | 23.2 | 26 | 28.6 | 34.8 | 34.8 | 39 | 42.8 | 52.2 |

| AT-HP PLUS + Ø20 | 36.3 | 40.6 | 44.6 | 47.2 | 54.4 | 61 | 66.9 | 70.8 |

| AT-HP PLUS + Ø25 | 52.3 | 58.6 | 64.4 | 68 | 78.5 | 87.9 | 96.6 | 102.1 |

Design resistance – Shear – VRd [kN] – Rebar

| Modelo | Design resistance – VRd – Carbon steel 5.8 [kN] | |||||||

|---|---|---|---|---|---|---|---|---|

| Non-cracked concrete | ||||||||

| hef = 8d | hef = 12d | |||||||

| C20/25 | C30/37 | C40/50 | C50/60 | C20/25 | C30/37 | C40/50 | C50/60 | |

| AT-HP PLUS + Ø8 | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 | 9.3 |

| AT-HP PLUS + Ø10 | 14.7 | 14.7 | 14.7 | 14.7 | 14.7 | 14.7 | 14.7 | 14.7 |

| AT-HP PLUS + Ø12 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 |

| AT-HP PLUS + Ø14 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 |

| AT-HP PLUS + Ø16 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 | 36.7 |

| AT-HP PLUS + Ø20 | 57.3 | 57.3 | 57.3 | 57.3 | 57.3 | 57.3 | 57.3 | 57.3 |

| AT-HP PLUS + Ø25 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

Design resistance – Bending moment – MRd [Nm] – Rebar

| Modelo | Design resistance – Bending moment – MRd [Nm] |

|---|---|

| AT-HP PLUS + Ø8 | 22 |

| AT-HP PLUS + Ø10 | 43.3 |

| AT-HP PLUS + Ø12 | 74.7 |

| AT-HP PLUS + Ø14 | 118.7 |

| AT-HP PLUS + Ø16 | 176.7 |

| AT-HP PLUS + Ø20 | 345.3 |

| AT-HP PLUS + Ø25 | 674.7 |

Instalación

Montaje

Tiempos de montaje

| Temperatura [°C] | -5°C | 0°C | 5°C | 10°C | 20°C | 30°C |

| Tiempo de curado | 45min | 15min | 12min | 9min | 4min | 1min |

| Tiempo hasta la solicitación | 9h | 4h | 1h30 | 60min | 30min | 20min |

Méthodes de perçage

| Brique pleine/Béton | perçage à percussion |

| Brique creuse | perçage rotatif |

| Béton cellulaire | perçage à percussion |

Installation parameters – Concrete

| Modelo | Installation parameters - Concrete | |||||

|---|---|---|---|---|---|---|

| Ø drilling [d0] [mm] | Max. fixture hole Ø [df] [mm] | Drilling depth (8d) [h0=hef=8d] [mm] | Drilling depth (12d) [h0=hef=12d] [mm] | Wrench size [SW] | Installation torque [Tinst] [Nm] | |

| AT-HP PLUS + LMAS M8 | 10 | 9 | 64 | 96 | 13 | 10 |

| AT-HP PLUS + LMAS M10 | 12 | 12 | 80 | 120 | 17 | 20 |

| AT-HP PLUS + LMAS M12 | 14 | 14 | 96 | 144 | 19 | 30 |

| AT-HP PLUS + LMAS M16 | 18 | 18 | 128 | 192 | 24 | 60 |

| AT-HP PLUS + LMAS M20 | 24 | 22 | 160 | 240 | 30 | 90 |

| AT-HP PLUS + LMAS M24 | 28 | 26 | 192 | 288 | 36 | 140 |

Spacing, edge distances and member thickness – Concrete

| Modelo | Spacing, edge distance and member thickness - Concrete | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Effective embedment depth (8d) [hef,8d] [mm] | Characteristic spacing for hef,8d [Scr,N] [mm] | Characteristic edge distance for hef,8d [ccr,N] [mm] | Min. member thickness for hef,8d [hmin] [mm] | Effective embedment depth (12d) [hef,12d] [mm] | Characteristic spacing for hef,12d [Scr,N] [mm] | Characteristic edge distance for hef,12d [ccr,N] [mm] | Min. member thickness for hef,12d [hmin] [mm] | Min. spacing [Smin] [mm] | Min. edge distance [Cmin] [mm] | |

| AT-HP PLUS + LMAS M8 | 64 | 192 | 96 | 100 | 96 | 288 | 144 | 100 | 40 | 40 |

| AT-HP PLUS + LMAS M10 | 80 | 240 | 120 | 110 | 120 | 360 | 180 | 150 | 50 | 50 |

| AT-HP PLUS + LMAS M12 | 96 | 288 | 144 | 126 | 144 | 432 | 216 | 174 | 60 | 60 |

| AT-HP PLUS + LMAS M16 | 128 | 384 | 192 | 158 | 192 | 576 | 288 | 222 | 80 | 80 |

| AT-HP PLUS + LMAS M20 | 160 | 480 | 240 | 190 | 240 | 720 | 360 | 270 | 100 | 100 |

| AT-HP PLUS + LMAS M24 | 192 | 576 | 288 | 222 | 288 | 864 | 432 | 318 | 120 | 120 |

Installation parameters – Rebar

| Modelo | Installation parameters - Rebar | ||

|---|---|---|---|

| Ø drilling [d0] [mm] | Drilling depth (8d) [h0=hef=8d] [mm] | Drilling depth (12d) [h0=hef=12d] [mm] | |

| AT-HP PLUS + Ø8 | 12 | 64 | 96 |

| AT-HP PLUS + Ø10 | 14 | 80 | 120 |

| AT-HP PLUS + Ø12 | 16 | 96 | 144 |

| AT-HP PLUS + Ø14 | 18 | 112 | 168 |

| AT-HP PLUS + Ø16 | 20 | 128 | 192 |

| AT-HP PLUS + Ø20 | 25 | 160 | 240 |

| AT-HP PLUS + Ø25 | 32 | 200 | 300 |

Spacing, edge distances and member thickness – Rebar

| Modelo | Spacing, edge distance and member thickness - Rebar | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Effective embedment depth (8d) [hef,8d] [mm] | Characteristic spacing for hef,8d [Scr,N] [mm] | Characteristic edge distance for hef,8d [ccr,N] [mm] | Min. member thickness for hef,8d [hmin] [mm] | Effective embedment depth (12d) [hef,12d] [mm] | Characteristic spacing for hef,12d [Scr,N] [mm] | Characteristic edge distance for hef,12d [ccr,N] [mm] | Min. member thickness for hef,12d [hmin] [mm] | Min. spacing [Smin] [mm] | Min. edge distance [Cmin] [mm] | |

| AT-HP PLUS + Ø8 | 64 | 192 | 96 | 100 | 96 | 288 | 144 | 100 | 40 | 40 |

| AT-HP PLUS + Ø10 | 80 | 240 | 120 | 110 | 120 | 360 | 180 | 150 | 50 | 50 |

| AT-HP PLUS + Ø12 | 96 | 288 | 144 | 126 | 144 | 432 | 216 | 174 | 60 | 60 |

| AT-HP PLUS + Ø14 | 112 | 336 | 168 | 148 | 168 | 504 | 252 | 204 | 70 | 70 |

| AT-HP PLUS + Ø16 | 128 | 384 | 192 | 168 | 192 | 576 | 288 | 232 | 80 | 80 |

| AT-HP PLUS + Ø20 | 160 | 480 | 240 | 210 | 240 | 720 | 360 | 290 | 100 | 100 |

| AT-HP PLUS + Ø25 | 200 | 600 | 300 | 264 | 300 | 900 | 450 | 364 | 125 | 125 |